Should I Use Recycled Plastic or Wood for Sustainable Signage?

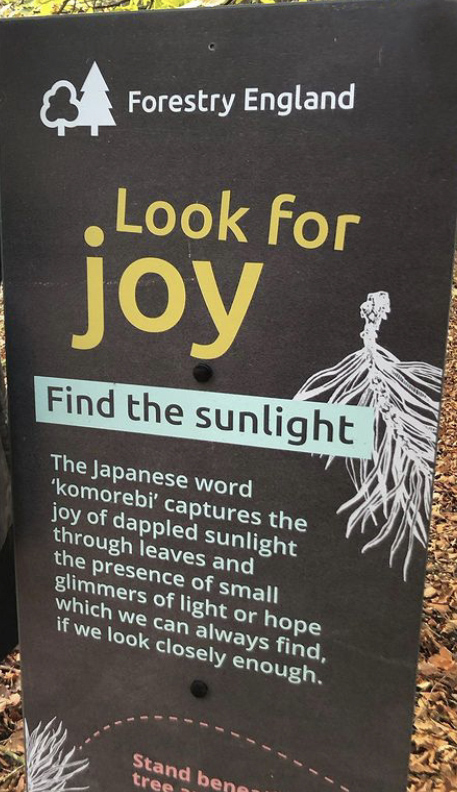

A couple of weeks ago, myself and Kate (co-owner of Inspirwood) took our Border Terrier dog Woody out for a woodland walk to one of our favourite places, Haldon Forest, near Exeter. We can remember this place before it became rather commercialised and is part of the Forestry England’s plantations. Having said that, the place is still great, with cycling routes, walks, bridle tracks and a great woodland café.

After a while walking around, we saw some newly produced trail signage. Great graphics and directions, but I was struck by the use of recycled plastic as a substrate for the sign. Being in a woodland, it felt wrong to have a man-made substrate lingering in amongst the Oak, Sycamore and the Fir trees. So, investigating further and discussing this with the lovely Rangers, we found that they had used rHDPE plastic.

The Ranger was keen to tell me that they can also be recycled after use, so she was very pleased with them. Of course, this made me think about whether it was right to use this material, or should they have used wood which would “seem” more in keeping with the environment? I wanted to share my findings below on this, along with my opinion about this recycled/recyclable material.

What is rHDPE?

rHDPE stands for Recycled High Density Polyethylene and is one of the easiest and most recycled types of plastic. The virgin plastic, which can be from milk bottles, detergent bottles, bleach bottles, shampoo bottles, and Tupperware for example, is first collated into their types, washed and sorted into colours. It is usually ground down into pellets, then melted down and pressed into other new recycled items.

So that’s great right – it means plastic doesn’t go into landfill sites and stops the use of virgin plastic being produced?

Actually, this is a bit ambiguous, so yes and no. The plastic is taken from waste virgin material, which in theory is heading to landfill. In the UK however, most landfill sites are being closed down, in preference to heat transfer plants, so the hope is that anything that can’t be recycled will be burnt to create energy. There are concerns however due to it releasing further carbon and chemicals during this process, but that’s another blog post in itself!

The HDPE plastic that is turned into recycled plastic has to have a percentage of new virgin plastic and a dye added to it, which gives it strength and gives it a uniform colour (usually black). If you read the manufacturers websites, they say this is “a small amount”, however, in practical terms, it is about 10-15%. Which is why the manufacturers say that HDPE can be recycled up to 10 times. It’s often called ‘open loop recycling’.

If you think about this, 10% of virgin plastic is used in production of rHDPE, so over the course of its lifetime, it has generated 100% more plastic waste.

The 10% that can’t be recycled and the final item, still has to go somewhere. It can’t go to landfill as it takes 1000s of years to degrade and actually just becomes micro plastic if it did, so where will it go? – into the heat transfer plant? Shot up into space? Released into the oceans?

Furthermore, we have to think about the carbon footprint in the production of this recycled plastic material. According to studies, this could be about 30% of the final weight of the product. So, for every 1 tonne of recycled plastic, there is 300kg of CO2 released into the atmosphere.

In conclusion, even recycled plastic ADDS to our carbon emissions!

So, let’s compare this to a printed wood sign as an alternative to recycled plastic as your substrate to signage?

Well, I won’t try to be biased on this, as printing onto wood is what we do, but there is a reason we chose this substrate, and here is why.

Wood is a natural product, it is a fantastic renewable source if managed properly, and is also biodegradable and recyclable. Be sure that the wood used of course is either FSC® or PEFC certified, that way you can be sure that the trees come from managed forests, and the company that harvests the wood is socially and ethically audited.

Of course, not all types of wood are equal, MDF (Medium Density Fibre) for example is made from wood, dust and glue. The glue in this case isn’t all that great and this also means it technically isn’t biodegradable in normal circumstances. MDF is made from recycled timber though and the glues are made from natural sources in most cases. Plywood is a lot better as it uses what I call “proper wood veneer”, and solid timber which is literally wood cut from the tree is the ultimate in natural resources.

What are the environmental benefits of wood as a substrate for printing onto?

Our most common material that we use in our products is Birch Plywood, and for good reason. Firstly, it’s from a small wood mill in Finland, and one of the most sustainable managed FSC / PEFC wood mills in the world. The carbon footprint of plywood has a positive net figure.

Confused? Let me explain, timber is known to naturally reduce CO2 in the atmosphere by absorption and it releases oxygen in return. For every dry tonne of manufactured timber, around 1.8 tonnes of CO2 is removed from the atmosphere. CO2 is used when manufacturing and transporting the wood, but even with this taken into account, the CO2 locked into the wood far outweighs the amount it has taken to manufacture it. Compare this to rHDPE, taking Carbon capture alone into consideration, it is a clear winner.

Why are Trees considered as the Earths lungs?

Because, did you know that one, 10 year old broad leaf tree – so think a nice birch tree in your local woodland – is expelling enough oxygen to support 4 adults per day? This highlights the real need to choose FSC / PEFC certified timber, so you know the trees are replanted and managed properly rather than clearing ancient woodlands, or even worse, timber from rainforests.

Is wood a good option for outdoor signage?

Yes! Different wood species and types last longer than others, but if you compare to plastic signs, then an alternative can definitely be found.

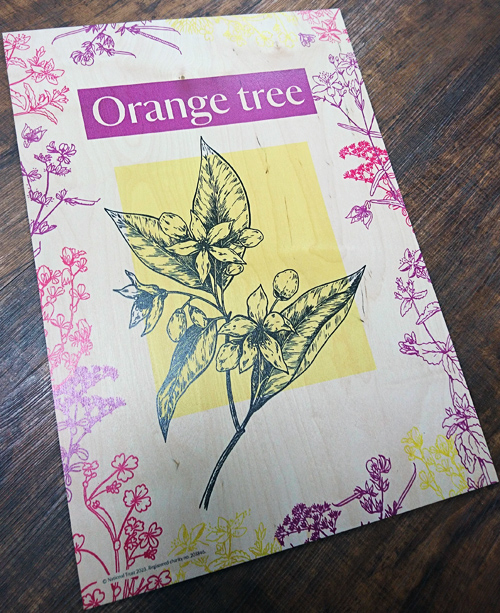

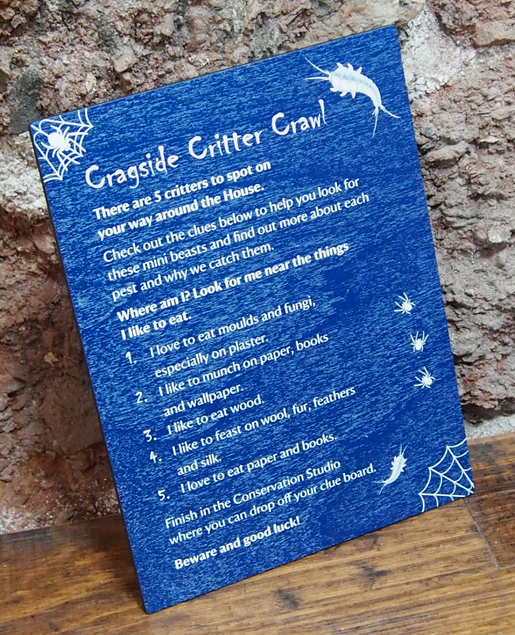

We produce a range of temporary wooden signs which we go head-to-head with Corex and Foamboard plastics. They can last just as long in the elements, as well as staying on budget. Other options are available for permanent wooden signs which will last as long as aluminium signage such as Dibond and Vinyls, yet still having the benefits as mentioned above. One such company who has changed over from plastic to wood is The National Trust.

So, to conclude, wood is better than plastic?

We think so, at least in this scenario. Wood removes carbon from the atmosphere, helping reduce climate change whereas plastic adds carbon!

There will always be a need for some plastics, and recycled plastics especially, however, in my opinion, it has to be for the right reasons, such as long-term use in buildings and underwater applications, but never for promotional purposes!